The need for high-speed cable stranding machines has exploded in recent years, driven by the growing demand for communication cables in a variety of industries. These machines are essential for fabricating large quantities of cable with accuracy. Modern high-speed stranding machines utilize cutting-edge technology to achieve exceptional output, allowing manufacturers to satisfy the growing market demands.

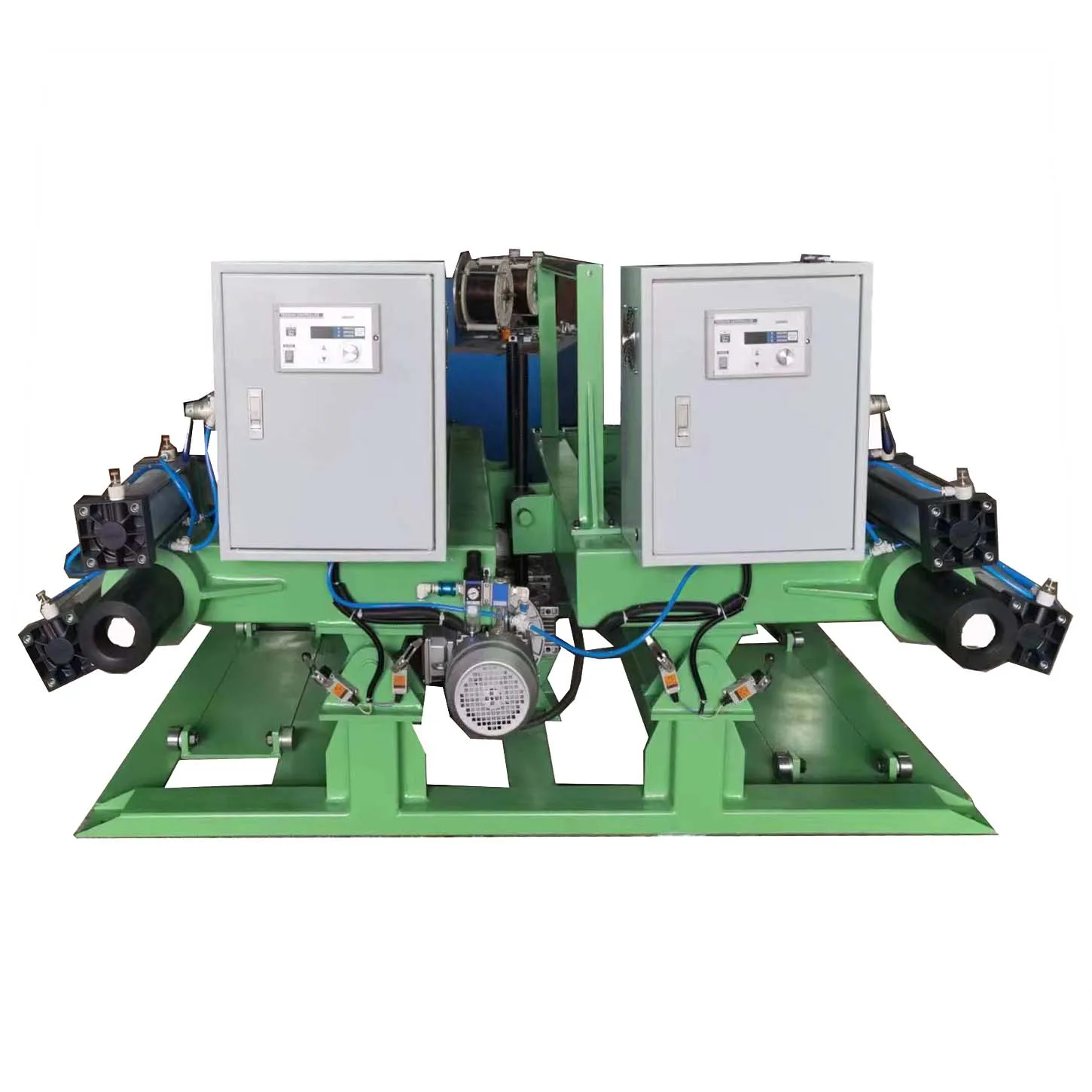

Some of the key attributes that distinguish high-speed cable stranding machines include: Programmable operation for increased output, accurate strand alignment to ensure cable integrity, and heavy-duty construction for long service periods.

- Furthermore, these machines often incorporate advanced monitoring systems to record performance metrics in real time, allowing manufacturers to improve their production processes.

- Ultimately, high-speed cable stranding machines have become an critical component of modern cable manufacturing, enabling producers to adjust to the ever-changing demands of the market.

State-of-the-Art Wire Twisting Technology: Precision and Efficiency

Wire twisting has evolved significantly over the years, propelled by advancements in technology. Today, advanced wire twisting machinery boasts remarkable precision. These systems employ intricate controls to ensure that wires are twisted with incredible consistency and force. The result is a product of exceptional quality, exceeding the capabilities of manual methods.

Furthermore, these advanced technologies offer enhanced efficiency. Automated machines can twist wire at rapid speeds, dramatically increasing production output. This translates to significant cost savings and reduced lead times for manufacturers.

In addition to precision and efficiency, advanced wire twisting technology also improves the reliability of the final product. By minimizing variations in twist density, these systems contribute to the overall durability and performance of wire harnesses, cables, and other applications.

Customizable Cable Stranding Solutions for Numerous Industries

In today's rapidly evolving technological landscape, industries across the board require cable stranding solutions that are as unique as their applications. Conveniently, advancements in manufacturing processes have led to a surge in flexible cable wire twisting machine stranding options, catering to the particular needs of diverse sectors. From reliable cables for aerospace and transportation to intricate stranding designs for medical devices and process automation, the possibilities are truly boundless.

- These kinds of solutions deliver a range of perks, including improved conductivity, enhanced durability, and tailored performance characteristics.

- Additionally, customizable cable stranding allows for efficient space utilization and minimizes the overall weight of cables, making them appropriate for applications where size and weight are critical considerations.

Via their ability to satisfy the unique demands of various industries, customizable cable stranding solutions have become an essential component in propelling innovation and performance across diverse sectors.

Wire Twisters: Delivering Optimal Strand Construction

In the realm of wire processing, where precision and reliability are paramount, strand fabrication tools emerge as indispensable assets. These specialized devices excel at creating uniformly twisted strands, a crucial element in diverse applications ranging from aerospace components to everyday electronics. A skilled operator guide the wire twister's operation, ensuring that each strand adheres to exacting tolerances. The result is a tightly wound, robust structure capable of withstanding mechanical forces while maintaining its integrity.

Wire twisters come in various configurations, each tailored to handle specific wire gauges and materials. From single-strand twists to complex multi-wire formations, these versatile tools accomplish a wide array of designs.

Precise twisting techniques is essential for maximizing the performance of electrical conductors. Through their ability to create uniformly twisted strands, wire twisters ensure consistent electrical conductivity, mechanical strength, and overall reliability.

High-Tech Cable Manufacturing Equipment: Streamlining Production

The cable manufacturing industry is continuously evolving, driven by the need for higher efficiency and accuracy. Technological advancements have emerged as a key driver in achieving these goals. Automated cable manufacturing equipment offers numerous strengths that significantly enhance the production process.

Additionally, these systems reduce human mistakes and improve quality control. This leads to faster production rates and reduced overall expenses.

- State-of-the-art sensors and software enable precise calculation of cable dimensions, ensuring consistent product quality.

- Automated arms perform repetitive tasks with speed, maximizing production output.

- Integrated systems track the entire manufacturing process, providing real-time data for process optimization.

As the demand for cables grows, automated cable manufacturing equipment becomes increasingly vital for companies to stay in the lead. By embracing automation, the industry can attain greater efficiency, productivity, and product quality.

Leading Manufacturers of Cable Stranding Equipment

The cable production industry relies heavily on sophisticated machinery for stranding and twisting cables. Several renowned global companies have established themselves as key players in this sector, providing a comprehensive portfolio of high-performance machines to meet the evolving needs of manufacturers worldwide.

- Notable of these prominent players include:

- General Electric

- Phoenix Contact

- Nexans

These companies continuously invest innovation and research and development, delivering cutting-edge technology that enhances efficiency, precision, and reliability in cable stranding and wire twisting processes.